Rubber is a crucial material used across various industries, from automotive manufacturing to aerospace, medical devices, and construction. The two primary types of rubber are natural rubber and synthetic rubber. Understanding the key differences, performance characteristics, and applications of these rubber types can help businesses make the most informed choices to meet their needs.

In this article, we’ll dive into the definitions, uses, and advantages of both natural rubber and synthetic rubber, helping you choose the right material for your specific requirements. Whether you’re looking for the best rubber for automotive tires, industrial seals, or medical products, this guide provides valuable insights.

What is Natural Rubber?

Natural rubber, also known as latex, is derived from the sap of the rubber tree (Hevea brasiliensis). The process of harvesting natural rubber involves tapping the rubber tree to collect latex, which is then processed into solid rubber. The primary polymer in natural rubber is polyisoprene, which provides its unique flexibility and strength.

Natural rubber is well-regarded for its high elasticity and tear resistance, which makes it highly effective in products that demand durability and flexibility, such as tires, medical gloves, and footwear.

What is Synthetic Rubber?

Synthetic rubber is made through chemical processes using petroleum-based raw materials, such as styrene, butadiene, and isoprene. The production of synthetic rubber allows for the engineering of rubber with specific properties, such as temperature resistance, oil resistance, and chemical resistance. Popular types of synthetic rubber include styrene-butadiene rubber (SBR), butadiene rubber (BR), and neoprene.

Synthetic rubber is widely used across industries like automotive, aerospace, and electronics, thanks to its customizable properties and more consistent performance under various conditions.

Key Differences Between Natural and Synthetic Rubber

Though natural and synthetic rubber share many applications, they differ significantly in properties, cost, and performance. Here are the key factors that differentiate these two types of rubber:

1. Source and Production Process

- Natural Rubber: Harvested from the latex of rubber trees, natural rubber is a renewable resource, though its supply can be affected by environmental factors.

- Synthetic Rubber: Created through chemical processes using petroleum-based materials, synthetic rubber can be manufactured with specific properties suited to the demands of various industries.

2. Elasticity and Strength

- Natural Rubber: Known for its high elasticity, natural rubber can stretch without breaking and has superior tear resistance, making it ideal for products like automotive tires and seals.

- Synthetic Rubber: Synthetic rubbers generally don’t match the elasticity of natural rubber but can be tailored for specific uses, including chemical resistance or high-temperature performance.

3. Durability and Aging Resistance

- Natural Rubber: Natural rubber is vulnerable to oxidation, UV degradation, and heat exposure. Over time, it may lose its properties unless treated with protective chemicals.

- Synthetic Rubber: Many types of synthetic rubber, like neoprene and EPDM, offer superior resistance to environmental factors such as UV and heat, making them more durable in harsh conditions.

4. Cost and Availability

- Natural Rubber: While expensive to harvest, natural rubber offers excellent properties but is subject to market volatility due to climate changes affecting rubber tree harvests.

- Synthetic Rubber: Generally more cost-effective and available in greater quantities, synthetic rubber production depends on petroleum-based materials, which offer stable pricing.

5. Environmental Impact

- Natural Rubber: While renewable, the production of natural rubber can lead to deforestation and other environmental concerns. Sustainable practices like certified rubber harvesting aim to reduce this impact.

- Synthetic Rubber: Despite being derived from petrochemicals, efforts to use renewable resources and improve production efficiency have made synthetic rubber more environmentally friendly over time.

Applications of Natural Rubber

Natural rubber continues to play a pivotal role in several industries, including:

- Automotive: Due to its flexibility and abrasion resistance, natural rubber is essential in the production of car tires, especially for high-performance vehicles.

- Industrial Seals and Gaskets: With its elasticity and tear resistance, natural rubber is widely used for gaskets and seals, ensuring leak-proof seals in industrial machinery.

- Footwear: Sports shoes, boots, and slippers often feature natural rubber soles for their shock absorption properties.

- Medical Devices: Natural rubber gloves, catheters, and condoms rely on natural rubber’s biocompatibility for safe and effective use.

Applications of Synthetic Rubber

Synthetic rubber has become indispensable across various sectors due to its tailored performance characteristics:

- Automotive: Widely used in tires, seals, and hoses, synthetic rubber such as styrene-butadiene rubber (SBR) offers wear resistance and oil resistance.

- Aerospace: Special types like neoprene and EPDM are used in aerospace components, offering excellent chemical resistance and high-temperature performance.

- Construction: In the construction industry, synthetic rubber is used for roofing membranes, insulation, and waterproofing, due to its weather resistance and durability.

- Electronics: Silicone rubber and other synthetic variants are essential in the electronics industry for seals, gaskets, and vibration dampening.

Choosing Between Natural and Synthetic Rubber

When deciding between natural rubber and synthetic rubber, it’s essential to consider factors like performance requirements, cost-efficiency, and environmental impact. Natural rubber excels in applications requiring elasticity and tear resistance, whereas synthetic rubber is more suited to temperature extremes, chemical resistance, and long-term durability.

For industries such as automotive manufacturing, aerospace, and medical supplies, making the right choice can optimize product performance and cost-effectiveness.

The Future of Rubber Materials

Both natural rubber and synthetic rubber continue to be essential materials across diverse industries. With advances in production techniques and sustainable practices, both types of rubber are evolving to meet the growing demands of modern manufacturing, automotive design, aerospace, and other fields.

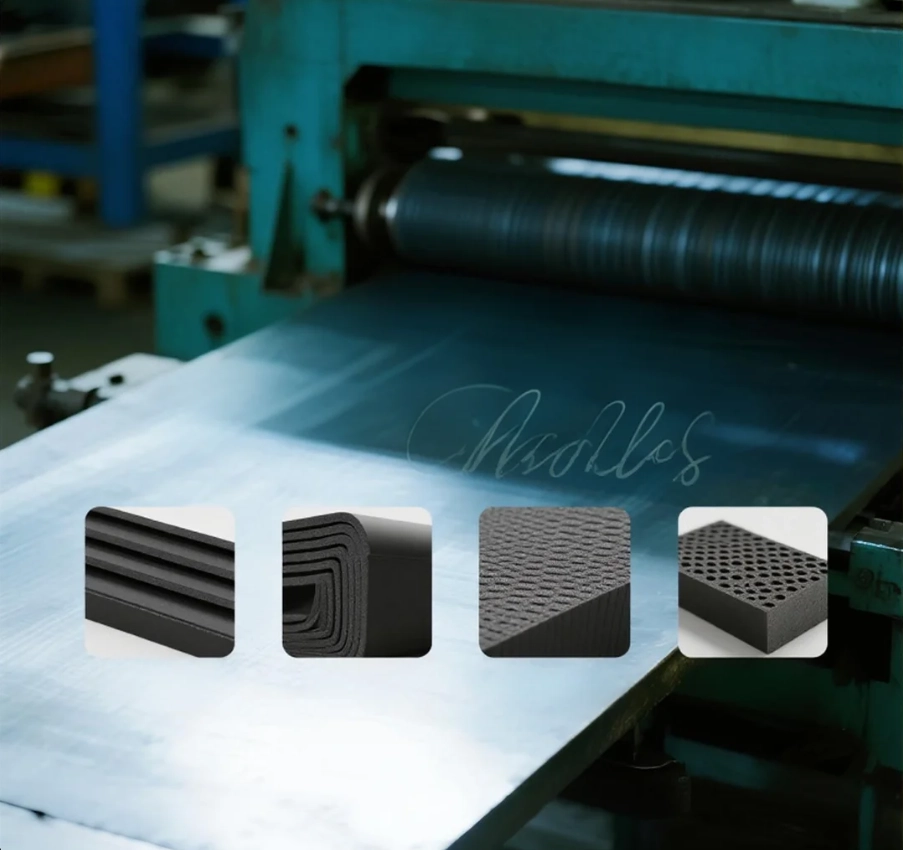

For companies like Grand, which specializes in producing rubber products such as rubber sheets, non-slip mats, sealing strips, and gaskets, choosing the right material is crucial. Their expertise in producing both natural and synthetic rubber products ensures that businesses get the optimal performance and durability for their specific needs, whether in petroleum, chemical industries, machinery manufacturing, or electric power sectors.

Whether you need rubber sheets, gasket seals, or customized rubber molded products, Xuancheng Grand Rubber & Sealing Technology Co., Ltd. provides high-quality products tailored to your specifications, supported by advanced production processes and outstanding customer service.